At low speed when I first push or release the gas, I hear a click sound like it is in the dash. Has anyone noticed this? The van operates fine, but I notice the little sound at times.

Clicking sound when I release and push on gas pedal

2 reading

buster

61 - 80 of 285 Posts

I know, seems like a pretty obvious design flaw for an axle that receives a lot of torque in both directions. Doubling the nut does the same thing.Whatever happened to the standard cotter keys used to hold axle nuts in place after torque? Am I just old school?

I would not replace the current nut, like mentioned they are designed to deform on install and some bits of engineering must have been used in their design. But this could be a candidate for doubling if the right thread and is shallow enough.I wonder if these would hold by themselves without doubling up?

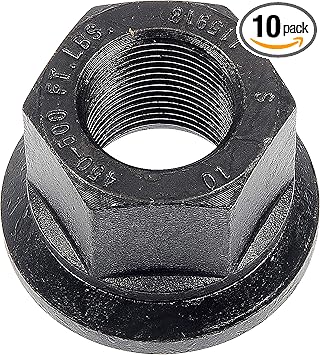

Amazon.com: Dorman 611-0030.10 M22-1.50 Wheel Nut Metric- 33mm Hex, 30.48 mm Length, 10 Pack Universal Fit : Automotive

Buy Dorman 611-0030.10 M22-1.50 Wheel Nut Metric- 33mm Hex, 30.48 mm Length, 10 Pack Universal Fit: Tire Repair Tools - Amazon.com ✓ FREE DELIVERY possible on eligible purchaseswww.amazon.com

LMAO @ your thumbnail pic!Whatever happened to the standard cotter keys used to hold axle nuts in place after torque? Am I just old school?

I hear you on the old school nuts. To be honest I always thought all axle nuts came with the soft lip to be staked into the axle groove.

Btw, the issue is not unique to Chrysler, searching on Google I found many other American cars are having the same issue of the axle nuts coming lose.

I really like how the Japanese do it, keeping it simple, no none sense.. All my Hondas, Subaru and Toyota cars have never had this problem.

Model Year:

2022

Gas / Hybrid:

Hybrid

Trim:

Touring L

Thanks for the advice...I'm wondering now if I should just bite the bullet and do this fix myself or stay the course with the dealership and get an "official" fix. I feel like I should take one for the team and get a Star Case opened in the hopes of getting a TSB published, even if it means repeated visits. My service writer and the tech seem more receptive to me now that I brought in the vehicle with the troubleshooting steps and fix in hand.I would not replace the current nut, like mentioned they are designed to deform on install and some bits of engineering must have been used in their design. But this could be a candidate for doubling if the right thread and is shallow enough.

I used to work on Airplanes' landing gear actuators years ago (Boeing, Douglas, Airbus & Lockheed Martin), it's where I learned some of the automotive mechanics foundation I have today. I've thought of drilling a side of the added doubled up axle nut to do something similar as they do in airplanes with safety wires, but then, you'd have to drill the tip of the axle to have something where to attach the safety wire to. This may really work/hold, but I'm not sure if the bit of counterweight from the wire may throw off the tire balancing a bit, plus the fact that the axle steel might super tough to drill.

![Image]()

Attachments

-

2.5 MB Views: 36

Hmmm. for those that know what I'm asking, does the above mentioned noise sound like similar to that of a driveshaft with a loose/dry u-joint?

Mine has such a noise, and I've wondered if anything was wrong. I guess I'll get out my torque wrench and check. BTW, mine is not AWD, as mentioned in the TSB.

Mine has such a noise, and I've wondered if anything was wrong. I guess I'll get out my torque wrench and check. BTW, mine is not AWD, as mentioned in the TSB.

Lacompas, what do you mean by a "secondary nut"? It sounds like you're stating you believed they double nutted the axle shaft.My fix is still holding up. To be honest I think they just grabbed a secondary nut lying around the shop that worked.

Check post #46Lacompas, what do you mean by a "secondary nut"? It sounds like you're stating you believed they double nutted the axle shaft.

that "secondary nut" is not the way to properly fix the problem, although I realize it might work. That's what I would definitely call some southern engineering. Looks like a ghetto repair.My fix is still holding up. To be honest I think they just grabbed a secondary nut lying around the shop that worked.

Model Year:

2022

Gas / Hybrid:

Hybrid

Trim:

Touring L

Honest question, how would one fix it?that "secondary nut" is not the way to properly fix the problem, although I realize it might work. That's what I would definitely call some southern engineering. Looks like a ghetto repair.

The only way to prevent the axle nuts from backing out is by having them staked on the grooved end of the axle with a punch after the nut is torqued down. Why modern American cars' axles don't bring grooved axle ends is beyond me.. If you have a good solution/possible fix that may work please share it with us.that "secondary nut" is not the way to properly fix the problem, although I realize it might work. That's what I would definitely call some southern engineering. Looks like a ghetto repair.

Going back to the discussion of the axle nut torque values, I may be wrong, but I think the reason why our Pacifica's FSM states 120 ft/lb and not a higher torque (as we're used to seeing on other vehicles all the way up to 160-170 ft/lb), might be because our cars bring two piece axles. A higher torque may damage this axle. Though if applied properly, holding the wheel studs with a long/sturdy pry bar(preventing the hub from spinning), it should prevent the torque from being transferred all the way to the gear box.

Model Year:

2022

Gas / Hybrid:

Hybrid

Trim:

Touring L

You know, there is another topic as it relates to the half axles that I wonder if it might be related to this issue (or rather a symptom of this issue.Going back to the discussion of the axle nut torque values, I may be wrong, but I think the reason why our Pacifica's FSM states 120 ft/lb and not a higher torque (as we're used to seeing on other vehicles all the way up to 160-170 ft/lb), might be because our cars bring two piece axles. A higher torque may damage this axle. Though if applied properly, holding the wheel studs with a long/sturdy pry bar(preventing the hub from spinning), it should prevent the torque from being transferred all the way to the gear box.

Reading some of those threads makes me think the axle snapping off would very likely be related to the axle nut coming lose from its torque.. Hmm, I hope I never have to deal with a snapped axle. I will definitely look into safety wiring the nut to the axle somehow, we'll see.

Model Year:

2022

Gas / Hybrid:

Hybrid

Trim:

Touring L

Pictures or it didn't happen!Reading some of those threads makes me think the axle snapping off would very likely be related to the axle nut coming lose from its torque.. Hmm, I hope I never have to deal with a snapped axle. I will definitely look into safety wiring the nut to the axle somehow, we'll see.

Will definitely post pics when I get around to it. If the axles have their centers drilled out at their ends as some other manufacturers do, it will make it easier do drill a small hole through there.Pictures or it didn't happen!

Joined

·

55 Posts

Nevermind, wrong post

Joined

·

55 Posts

Mind sharing those steps/fix that you presented to your dealer? I'm about to go down this rabbit hole on Friday with mine and just assume show up with everything super clear and concise. Thanks in advance!Thanks for the advice...I'm wondering now if I should just bite the bullet and do this fix myself or stay the course with the dealership and get an "official" fix. I feel like I should take one for the team and get a Star Case opened in the hopes of getting a TSB published, even if it means repeated visits. My service writer and the tech seem more receptive to me now that I brought in the vehicle with the troubleshooting steps and fix in hand.

Model Year:

2022

Gas / Hybrid:

Hybrid

Trim:

Touring L

1. Get a Service Writer or Tech to sit in the van with youMind sharing those steps/fix that you presented to your dealer? I'm about to go down this rabbit hole on Friday with mine and just assume show up with everything super clear and concise. Thanks in advance!

2. If you have a PacHy, place it in "L" as it's easier to reproduce

3. Apply gas sharply (don't roll on slowly, you want it to be jerky), you will hear a clunk/click noise

4. Let off gas sharply (same as last step), you will hear a clunk/click noise

5. Have them check the axle nuts and tighten them, then repeat steps 1-4, the sound should be gone.

6. Axle nuts will need to be replaced but the likely permanent fix is doubling the axle nuts which the dealership might not do (depends on the tech and their policies).

Is this problem only related to Hybrid Pacificas? Gas only Pacificas don't have these symptoms?

61 - 80 of 285 Posts

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

-

?

- posts

- 243K

- members

- 40K

- Since

- 2016

We’re a forum community dedicated to Chrysler Pacifica owners & enthusiasts. Come join the discussion about upgrades, towing capacity, reliability, and more!

Top Contributors this Month

View All

SitKneelBend

82 Replies

ChryslerCares

68 Replies

BriPac

61 Replies